Soluzioni per la Lean Manufacturing

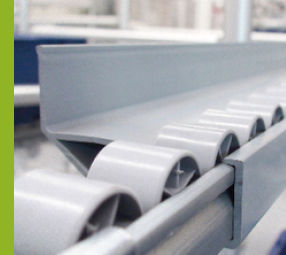

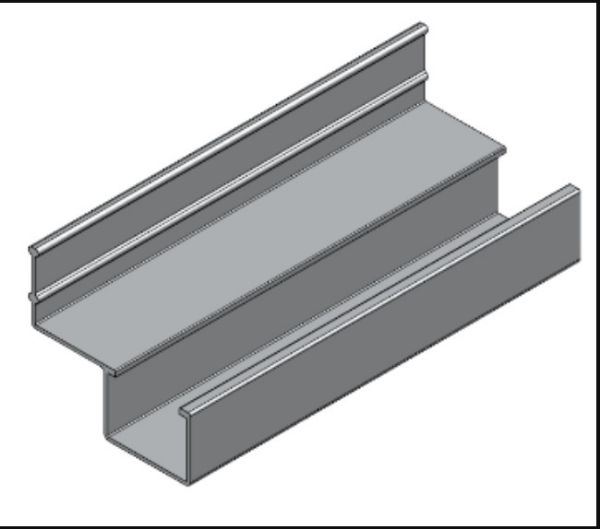

Guida centrale in alluminio per rulliera

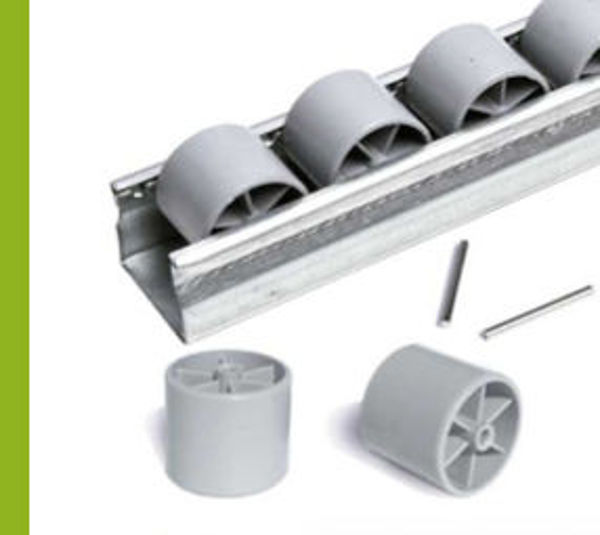

Tappo per tratto a rotelle

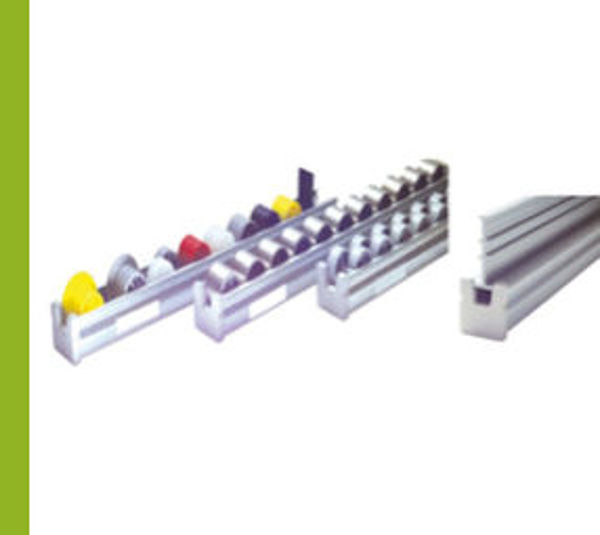

Tratto a rotelle P=33 mm

Guida laterale in alluminio per rulliera

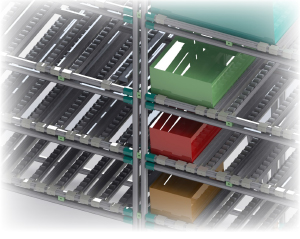

Magazzini supermarket e rulliere

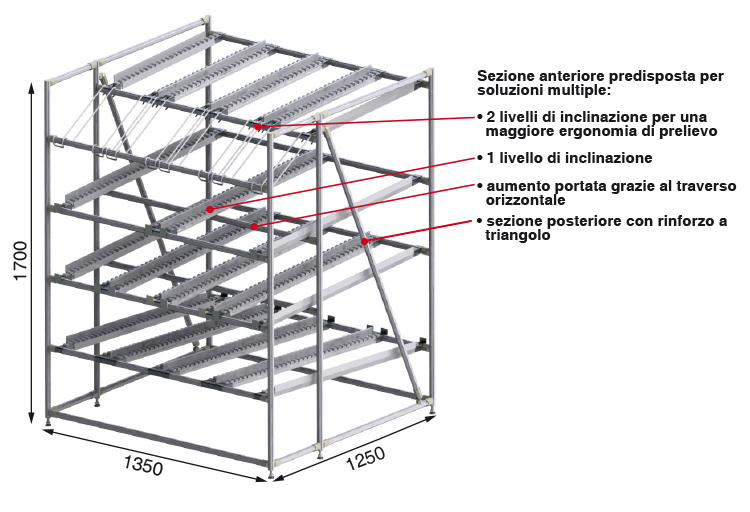

Un magazzino ben strutturato e ben organizzato richiede specifici requisiti che la Lean Manufacturing ci insegna: uno dei principi base dei magazzini supermarket è consentire di eliminare gli sprechi e rendere più lineari i processi produttivi. I magazzini organizzati secondo tale principio pongono una particolare attenzione a tutte quelle attività superflue che possono essere eliminate e permettono di ridurre gli spazi di stoccaggio dando cosi' maggiore attenzione agli approvvigionamenti riducendo gli stock di riordino.

I magazzini supermarket sono composti da strutture in alluminio, ecologico e riciclabile al 99%, e rulliere a gravità che sfruttano l'inclinazione.

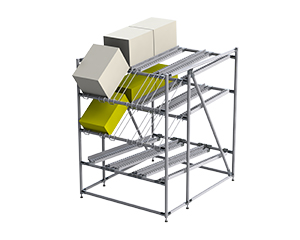

Le rulliere sono sistemi industriali per la movimentazione di carichi e merci all'interno dei magazzini o negli impianti di produzione: ottimizzano i tempi di trasferimento delle merci aumentando l'efficienza e riducendo il carico per gli operatori. I rulli di cui sono composte ruotano, sfruttando l'inclinazione e la forza di gravità, per far scivolare le merci senza ricorrere a un motore e renderle disponibili all'operatore permettendo anche di avere, se richiesto, un piano con inclinazione contraria per l'allontanamento dei vuoti.

Vi proponiamo per cui soluzioni personalizzabili su richiesta, in tempi rapidi e veloci. Progettiamo valutando il compito dell'operatore che, durante ogni operazione, deve trovare a disposizione tutti i pezzi di cui necessita e deve aver modo, quando il materiale all’interno di una scatola termina, di eliminarla e sostituirla. Entrambe le soluzioni si basano sul concetto FIFO (first in, first out): i nuovi materiali saranno così ripristinati direttamente dal retro della struttura. L’ultimo arrivato sarà l’ultimo a essere impiegato: sarà così che verranno utilizzati prima i componenti più datati. Un’organizzazione semplice, funzionale e automatica che consente di risparmiare tempo e ridurre gli sprechi.

E' possibile ottimizzare gli spazi creando magazzini supermarket per contenitori con misure standard 200x300 mm, 300 x 400 mm, 600 x 400 mm.

|

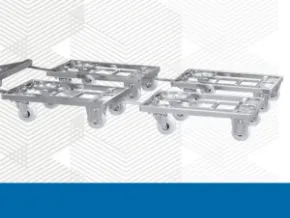

Blocchi Singoli

Blocco standard: la soluzione più usata che permette il picking sia dei singoli componenti che del contenitore. |

| Magazzino sfalsato: soluzione utilizzata per applicazioni in cui si necessita di un alto numero di ripiani e un facile accesso al prelievo dei singoli componenti. |

| Supermarket con doppia inclinazione: soluzione che offre il massimo livello di ergonomia nel prelievo. |

|

|

|

Blocchi multipliPer una soluzione ottimale consigliamo di evitare di creare magazzini supermarket troppo grandi ma utilizzare combinazioni di moduli di dimensioni ridotte. | ||||

| + |

| = |

|

Assemblaggio Supermarket con tempi ridotti al minimoCon i magazzini supermarket pre-assemblati dovrete solamente aggiungere i profili orizzontali per raggiungere la larghezza desiderata ed inserire i rulli. | ||

|

|

|

| 1. Ordinare le spalle del magazzino premontate | 2. Tagliare i profili orizzontali | 3. Aggiungere il numero di rulli desiderati |

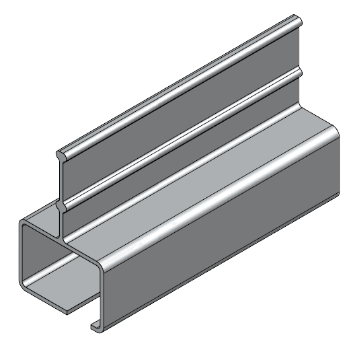

Profili doppiDove è richiesta una maggiore resistenza al carico, il Green Frame permette il raddoppio del profilo. |

|

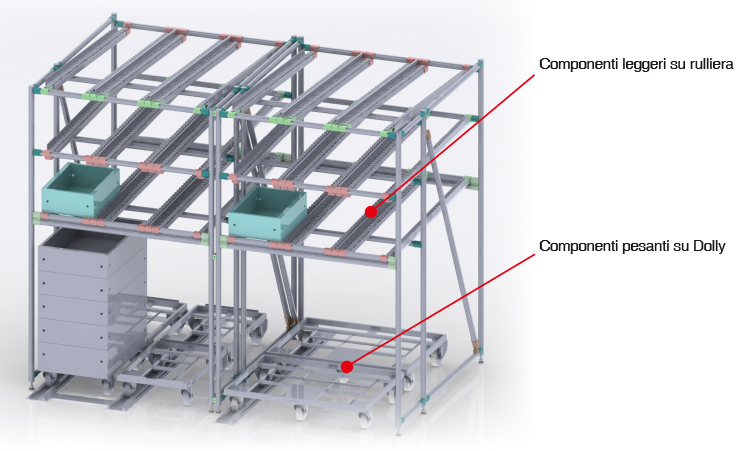

Ottimizzazione degli spazi |

|

Sistemi di ritorno dei vuotiEsistono 3 possibili sistemi di ritorno dei vuoti: Scegliete quello che più si adatta alla vostre esigenze in termini di spazio ed ergonomia | |

|

|

| Sistema di ritorno del vuoto a livello inferiore | Sistema di ritorno del vuoto laterale |

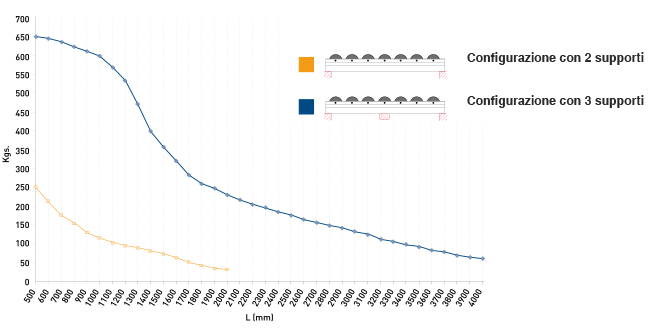

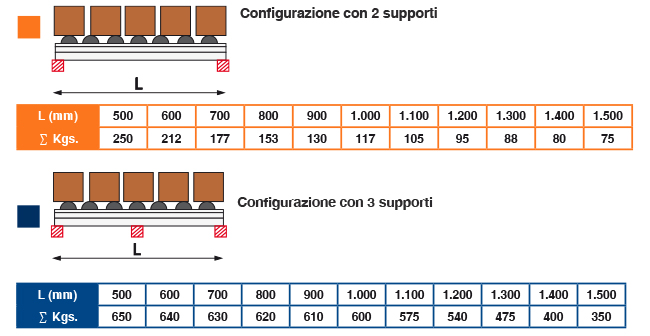

Analisi delle portate massime delle rulliere | ||

|  | |

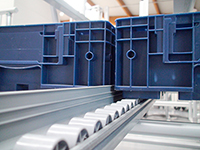

Dettagli guide in plastica | |||

Guida laterale | |||

|

|

| |

Guida centrale | |||

|

| ||

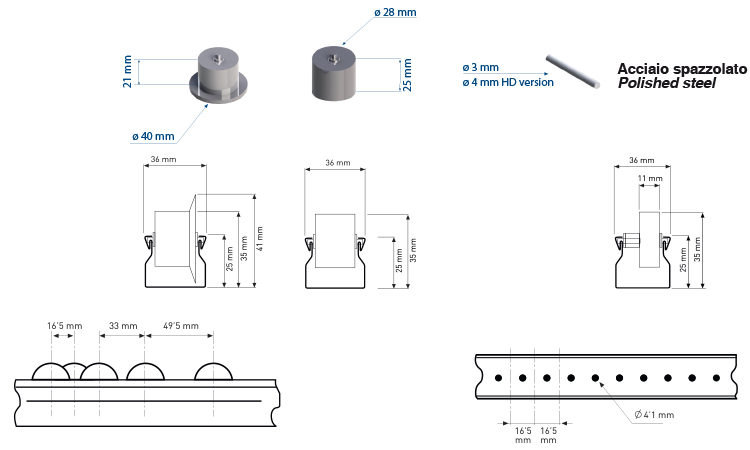

Dettagli rulli |

|