Soluzioni per la Lean Manufacturing

Heijunka

Approfondimenti

|

Heijunka è il termine giapponese per il livellamento della produzione. Grazie ad una pianificazione dettagliata dei processi produttivi, puntando su piccole quantità di materiali, viene garantita la sicurezza in termini di produzione e commerciali, evitando repentini cambiamenti sia dell'offerta che della domanda, con conseguenti squilibri e perdite, sia negli acquisti che nelle vendite. Si migliora la movimentazione e lo stoccaggio delle merci, si evitano gli sprechi e si instaura un rapporto più stretto con i fornitori, ottimizzando il lavoro del personale e l'orario di lavoro.

L'intervento si basa su due segmenti specifici:

Livellamento della produzione in volume

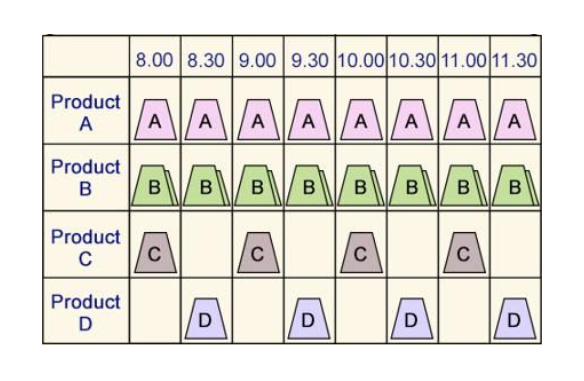

Il "volume di produzione livellato" è dato dalla distribuzione uniforme della produzione in un dato periodo di tempo: la domanda media viene valutata in un dato periodo di tempo, avendo a disposizione uno stock minimo per coprire eventuali richieste più elevate, evitando così un'offerta eccessiva. Il volume di produzione livellato dipende da: "varietà di produzione livellata"

Livellamento della produzione per mix di prodotti

La "varietà di produzione livellata" è la distribuzione uniforme del mix / varietà di produzione in un dato periodo di tempo: organizzare le produzioni in lotti per mantenere lo stesso livello di produttività nei diversi reparti, evitando che un singolo prodotto superi la media di produzione degli altri. Non corriamo dove non serve ma "tiriamo" l'intero flusso di produzione.

Come ralizzare una lavagna Heijunka

|  |

Struttura e Visualizzazione

|  | |

| Vista frontale | Vista laterale | |

|  | |

| Suddivisione temporale | Segnatempo | |

|  | |

| Soluzione standard | Soluzione diagonale per una migliore visualizzazione dei codici |