Soluzioni per la Lean Manufacturing

Lean Green Factory

Supporto per tastiera

Adattatore base rotonda con sfera C

Asta L = 90 mm con sfera C

Supporto VESA 75/100 con sfera C

Adattatore base diamante con sfera C

Asta flessibile con fissaggio base diamante L = 190 mm

Asta L = 150 mm con sfera C

Centralina Syncontrol 3

Colonna DL12

Approfondimenti |

L'azienda che utilizza metodi di produzione Lean e prodotti specifici per l'applicazione di questi principi è di fatto un'azienda di eccellenza dove tutto è finalizzato al miglioramento continuo e alla riduzione degli sprechi, che sono i principi di base del Lean alla base del Toyota Production System. |

Gli sprechi o MUDA (無駄) dal termine giapponese che identifica attività inutili, che non aggiungono valore o improduttive, sono identificabili in 7 categorie: |

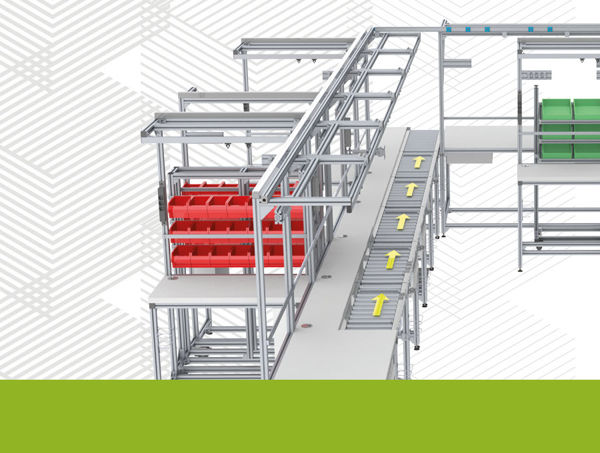

L'applicazione di questi principi e l'utilizzo di prodotti specifici che LeanProducts ha sviluppato in collaborazione con alcune delle principali aziende industriali del mondo, permetteranno alla Vostra azienda di trasformarsi in una LEAN GREEN FACTORY. Lavoriamo per trovare e costruire i migliori prodotti e le migliori soluzioni possibili, attenti alle problematiche mondiali quali ambiente, salute ed economia. ApplicationsQuesta sezione presenta una serie di componenti indispensabili per rendere le postazioni, le isole di lavoro e le linee di produzione ordinate ed efficienti al massimo. Prestiamo la massima attenzione all'ergonomia e alla salute dell'operatore con postazioni regolabili in altezza, sistemi di illuminazione con una luce di altissima qualità, senza sfarfallio, non abbagliante, a lunga durata, con pedane poggiapiedi che migliorano la postura e riducono l'affaticamento. Riduciamo i tempi di lavorazione organizzando lo spazio lavorativo in modo da dedicare il tempo solo alle attività che creano valore: miglioriamo la posizione degli strumenti di lavoro con cassettiere, portautensili, shadowboard personalizzabili e rendendiamo facilmente prelevabili i componenti necessari alla produzione con contenitori e vaschette di prelievo. Monitoriamo i prelievi con sistema Pick to Light che fornisce le istruzioni al personale del magazzino direttamente sullo scaffale indicando anche le quantità da prelevare, riducendo notevolmente la possibilità di errore, il tempo di ricerca dei codici ed evita di dover annotare maualmente le quantità prelevate. Promuoviamo il riconoscimento precoce delle problematiche di produzione per ridurre i tempi di reazione e i tempi di fermo e ottenere l'aiuto oppure il materiale necessario sulla linea più velocemente possibile grazie al sistema Andon Wireless. |

DOWNLOAD

Qui è possibile scaricare l'ultima versione del catalogo completo Lean Green Factory