Soluzioni per la Lean Manufacturing

FIFO Station

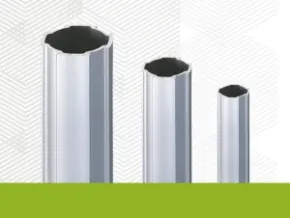

FIFO Station - Binari

FIFO Station - Terminali

FIFO Station - Adattatore

FIFO Station - Giunzione

FIFO Station - Distanziale per profilo 45x30 mm

FIFO Station - Vite di fissaggio

Approfondimenti

Le code FIFO (First In First Out) sono magazzini particolari a capacità finita nei quali i prodotti vengono stoccati uno dietro l'altro in modo tale che il primo prodotto che entra nel magazzino è il primo ad essere prelevato. Le code FIFO permettono al flusso di scorrere sebbene introducano un ritardo nel lead time di produzione più o meno grande a seconda della dimensione della coda. I processi divisi da una coda FIFO non sono completamente disaccoppiati: la lunghezza della coda è fissata e, una volta riempita, il processo a monte si deve obbligatoriamente fermare.

Il disaccoppiamento tramite code FIFO viene solitamente utilizzato quando:

- la macchina ha bassa affidabilità;

- la macchina, seppure riesca a lavorare tutti i prodotti nel tempo disponibile, non assicura che il tempo di ciclo per tutti i prodotti rimanga all’interno del takt time;

- la macchina non può lavorare tutti i prodotti nel tempo disponibile per via della presenza di prodotti con un tempo di ciclo maggiore del takt time;

- i processi sono fuori linea o esternalizzati lontani;

- si ha la convergenza di sottoflussi indipendenti nei quali non serve poter scegliere il prodotto dalla scorta.

|

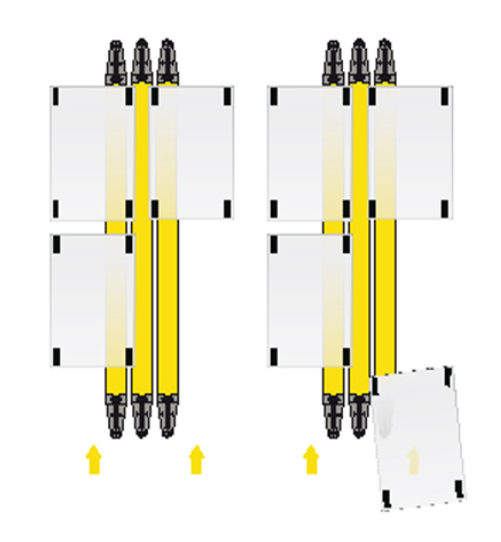

Come collegare binari e terminali, oppure binari, profilo di alluminio e terminali doppi

1) Utilizzare l'adattatore per collegare i due binari e i terminali e chiudere | 1) Utilizzare l'adattatore per collegare i binari al profilo e ai terminali doppi. | ||||

|  | ||||

.gif) |  | ||||

2) Togliere la pellicola di protezione del nastro adesivo nella parte posteriore, posizionare nella posizione desiderata e premere con forza. | |||||

|  | ||||

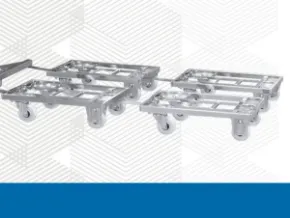

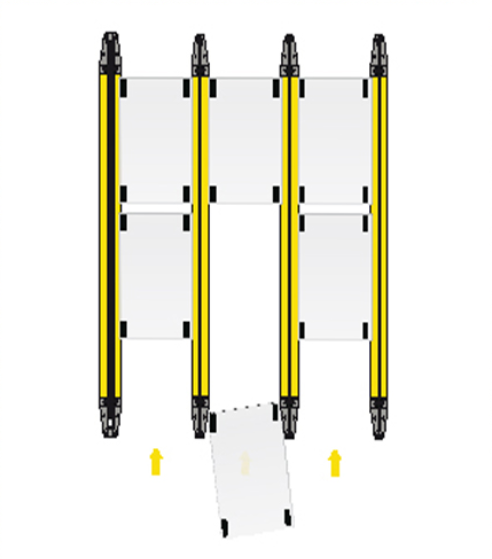

3) Affiancare le ruote del carrello al binario e posizionare il binario secondario. | |||||

|  | ||||

|  | ||||

| Guida del carrello su singolo lato, adatto a ruote in gomma | Guida del carrello sui due lati, adatto a ruote in poliammide | ||||

| 4) Fissare in maniera definitiva i terminali al pavimento utilizzando dei tasselli. | |||||

| |||||

Multimedia